Our "Flexible Circuit Design Guide" shows requirements for materials, product performance, and quality of Lenthor's Flexible Circuits.

Request the Design Guide >Flex Applications & Capabilities

- Single sided through 30 layers of flex

- Multi-layer Rigid Flex

- Staggered Layer Flex

- Dual Side Access

- Blind and Buried Vias

- Impedance Control

- Book Binder

| Description | Standard (Mils) | Supported (Mils) |

|---|---|---|

| Drill Hole to Copper Features Outer Layer Inner Layer - Signal Inner Layer - Plane |

0.010 0.012 0.015 |

0.008 0.010 0.012 |

| Drill Via Size Flex Rigid-Flex .040 Rigid-Flex .062 Rigid-Flex .093 Blind laser Via's |

0.008 0.010 0.012 0.016 0.010 |

0.004 0.008 0.008 0.015 0.008 |

| Annular Ring Print and Plate Pads Plate Laser Via Capture Pads |

0.005 0.010 0.006 |

0.004 0.006 0.005 |

| Trace Width 1 oz (0.0014) 1/2 oz (0.0007) |

0.005 0.004 |

0.003 0.003 |

| Spacing 1 oz (0.0014) 1/2 oz (0.0007) |

0.005 0.004 |

0.004 0.0035 |

| Misc. Silkscreen Line Width Copper to Board Edge Hole Size Tolerance Coverlay Opening Coverlay Web (Kapton) Layer Count Core Thickness (Rigid) Core Thickness (Flex) Processes |

0.007 0.010 0.006 0.005 annular ring 0.010 20 0.005 0.002 Bikini Prepreg Pouchless |

0.005 0.007 0.004 0.003 annular ring 0.006 24 0.003 0.001 |

- Flex Circuit and Rigid-Flex Circuit Design, Fabrication and Assembly.

- Complete in-house Flex Circuit and Rigid-Flex Circuit Turnkey and Consignment Assembly.

- Complete Design for Manufacturability consulting using Valor Genesis ODB+++ DFM software.

- Modern 50,000 Square Foot Manufacturing Facility.

- Time Critical (Quick-Turn) capability.

Lenthor's Flex Express Service

In today's ultra competitive marketplace, it's not just getting the right product to market, but getting there at the right TIME as well. Having your product available to your customers sooner can mean millions of saved revenue dollars and getting a big jump on "the other guys".

With this in mind Lenthor is proud to offer our Flex Express Service. Whether it is proof of design, engineering prototypes or short run production, Lenthor is here to serve your every delivery requirement. From single and double sided flex in 24 hours to rigid flex designs in 2 days, our employees are prepared to do whatever it takes to answer your call.

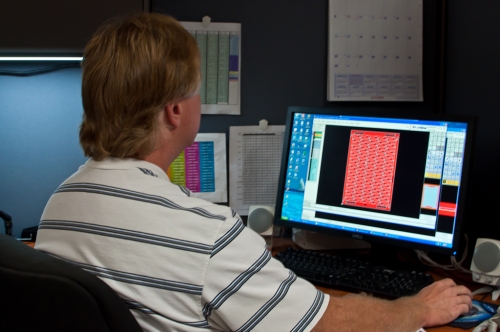

Our Valor Frontline Genesis 2000 Cad System allows our engineering department to tool your designs faster than ever before. This means your job hits our production floor within a matter of hours. The end result: you get your flex boards faster, with the same quality and reliability you have come to expect from a Lenthor product.

So if you're more concerned with staying ahead of the competition than keeping up with it, contact us and find out how our Flex Express Service can help keep "the other guys" at bay.

Lenthor Engineering RoHS Compliance Statement

Lenthor Engineering's primary role as your Flex and Rigid-Flex printed circuit board fabricator is to comply completely with the directives given to us regarding the fabrication of your printed circuits. This applies to the selection of the raw materials and specific surface finishes you specify within the documentation you supply to us. While Lenthor Engineering can and will provide direction, it is up to the specifying agent to direct us in the selection of the materials comprising the final build.

Lenthor Engineering continues to work with all of our suppliers of materials that could be affected by the new RoHS compliance statutes. We believe that we have identified those raw materials which do not meet compliance, and we have identified appropriate alternatives. We can provide specific materials information during your design phase. We have several alternative surface finishes available with industry standard HAL solder finish. For applications that require a solder finish we source lead-free alternatives.

Lenthor Engineering has prided itself on its commitment to meeting and exceeding all environmental compliance regulations. As a winner of the Susanne Wilson Environmental Achievement Award Lenthor Engineering is committed now and into the future to working with you to achieve RoHS compliance.